Four Common Types of Brake Squeaks

Do Your Brakes Squeak?

Any squeak in your vehicle can be annoying, especially if it continues to get worse. Here are four common types of squeaks that come from the brakes—common problems that come through the shop everyday—plus a fifth (bonus) brake noise—a scraping noise. I hope I can help you understand what's causing your brakes to squeak.

Four Common Types of Brake Squeaks

|

Disc Brakes

|

Drum Brakes

|

|---|---|

|

Morning squeak from overnight rain, dew, or condensation moisture .

|

Rear drum brake squeaks when shoe-to-backing-late contact points need lubrication.

|

|

Thinning brake pads set off brake wear indicator squeak.

|

|

|

Cheap brake pads with high metal content.

|

|

Two Types of Brakes

To make this discussion clearer I'll tell you that there are two types of brakes.

- Most brakes today are disc brakes, where a pad presses against a disc or rotor to stop the car. The first three squeaks described here come from disc brakes.

- Many cars have drum brakes on the back wheels, where a curved “shoe” presses against a hollow drum to stop the car. The last squeak here is made by drum brakes.

1. Disc Brakes Squeak After Car Sits Overnight

Most brakes squeak after sitting overnight. This is usually due to moisture from rain, dew, or condensation that collects on the surface of the rotors.

When moisture collects on the brake rotors, it causes a thin layer of rust to form on the rotor surface. As the rotor turns, the pads scrape the rust off the rotors, and then the rust gets caught on the leading edge of the brake pad. These fine particles of rust then get embedded into the leading edge of the pad and cause a squeak.

The only way to prevent this type of squeak is to garage your vehicle or store it in a climate-controlled environment. Rust on the rotors can also cause pad impressions on rotors, which in turn, cause a thumping noise or brake pulsation.

Rust Embedded in a Rotor

Noise From Rusty Rotors

2. Thinning Brake Pads

The brake wear indicator is another common cause of brake squeak. This sound starts when the brake pads are almost worn out and getting extremely thin. It’s a very effective warning that the that the brake pads are almost used up and need to be replaced.

The wear indicators are little metal tabs made of hardened steel. The manufacturers attach wear indicators in different ways: welding them on, using a rivet, or using a push-on clip attached to the edge of the brake-pad backing. These steel tabs are designed to hit the rotor before the brake pad totally wears out, warning the driver that the pad material is getting very thin and is about to create a metal-to-metal situation. You don’t want to get to that point because it means ineffective braking, and metal grinding and scratching on the rotor can damage the rotor’s smooth surface.

Wear Indicator Noise While Driving; Step on the Brakes and the Squeak Stops

3. High Metal Content in Brake Pads

Brake pads normally contain bits of metal, but some cheap brake pads are manufactured with very high metal content. They have large chunks of metal pressed into the pad material. These large pieces of metal drag on the rotor and cause a high pitched brake squeak.

Since brake pads sometimes can last between 30,000 to 40,000 miles, you'll have to listen to this annoying sound for months. This is one reason to spend a few extra bucks on quality brake pads. Another reason, of course, is that your brakes stop the car and quality helps. Don’t let twenty dollars stand between you and an accident that could end up costing you a lot more money.

To minimize squeaks from your brake pads, use brake pads with a high content of organic brake material (resin, rubber, Kevlar, fiber, or what-have-you). More organic brake material means fewer metal shavings in the brake pad, less squeaking, and less metal dust on your wheels. Metal particles in brake dust can discolor chrome or aluminum wheels.

4. Drum Brakes That Need Lubrication

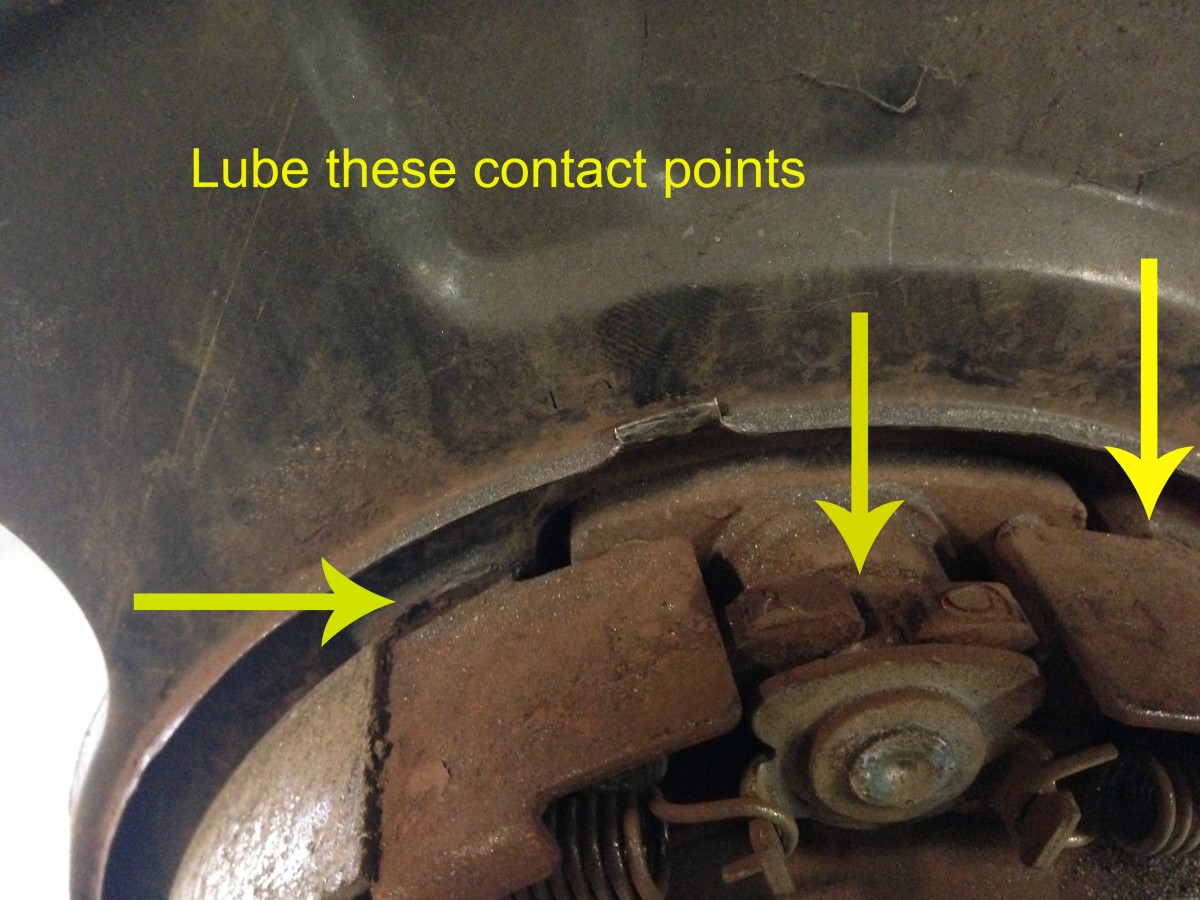

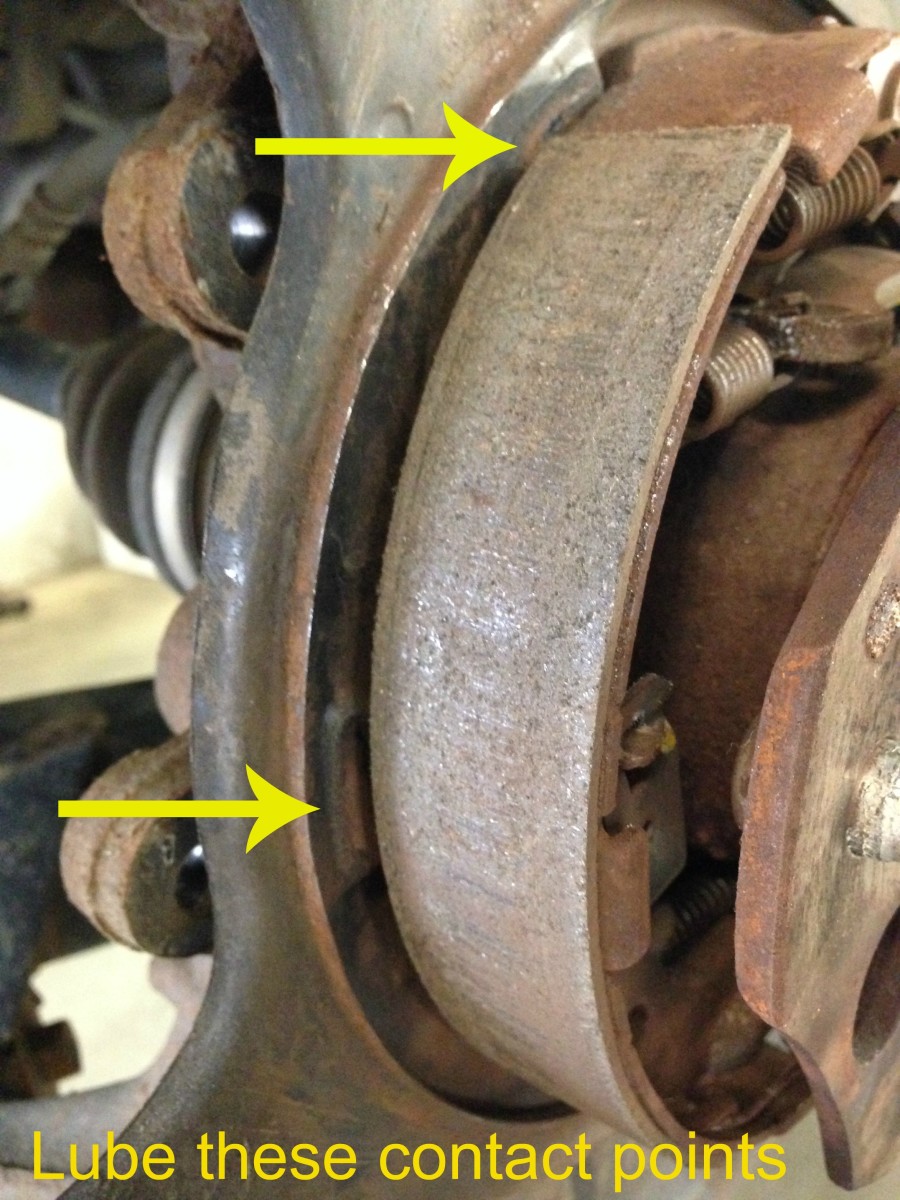

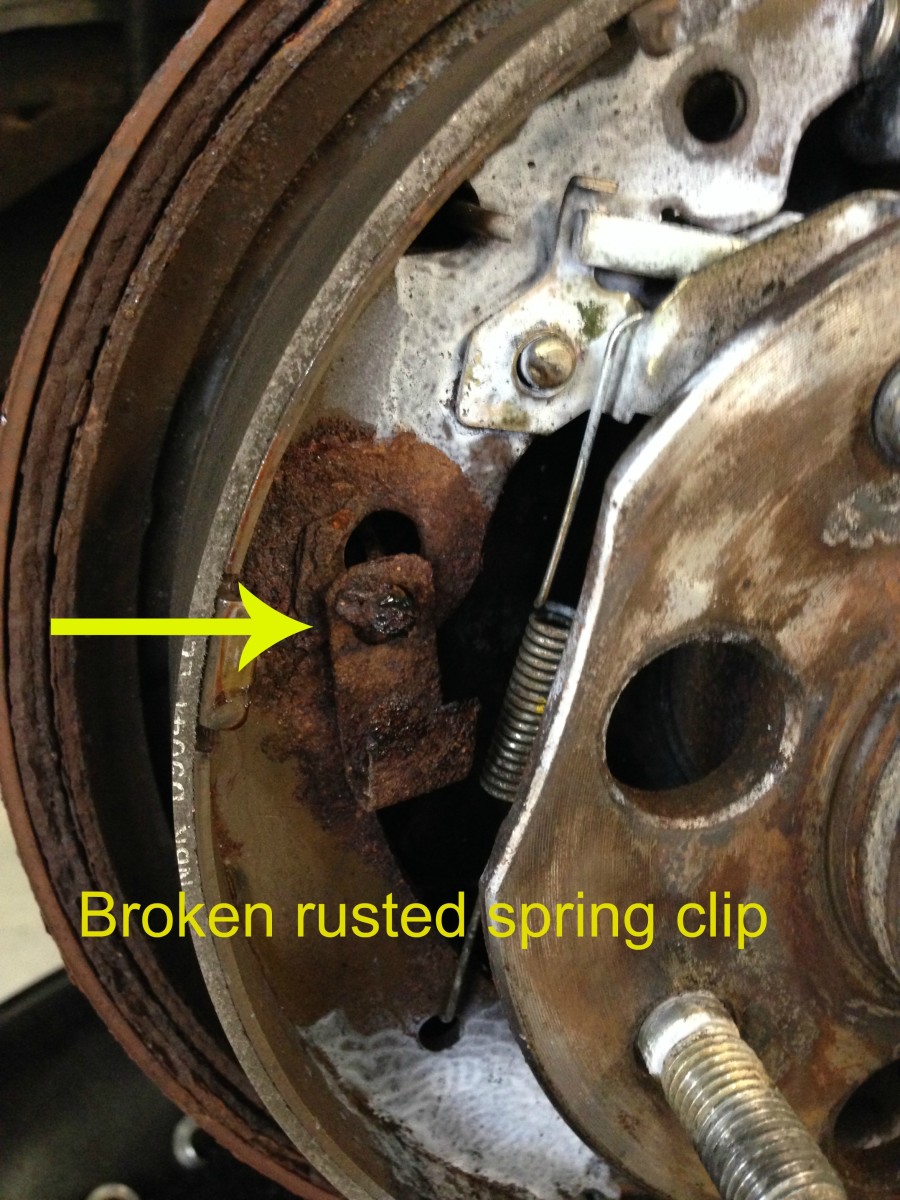

Have you ever heard a squeak from the rear brakes after pushing on the brake pedal? This is a sure sign that the shoe-to-backing-plate contact points need lubrication. If these contact points lose lubrication, the metal will begin to rust. Once this happens the shoes will scrape against the backing plate, causing a rhythmic squeaking noise with the rotation of the wheels. Most new vehicles have disc brakes on all four wheels, but drum brakes are still used on the rear wheels of some cars.

The best way to prevent this noise, or to repair it, is to keep the contact points lubricated, either with a high temperature anti-seize compound or a lube called Moly Paste 60. You use it on the back of brake pads and on all brake pad/shoe contact points, not on the brake pad or shoe surfaces themselves.

If you're looking for a lube to use on the caliper slide pins, use a Hi-Temp Wheel Bearing Grease like Amalie. If you use high quality products when doing your brake jobs, the time spent doing the job will be well worth it. In the long run, you'll have longer-lasting brakes with no headaches.

Moly Paste 60 is manufactured specifically for brakes, and will not melt or wash away. It comes in a small squeeze packet with all genuine Honda brake pad sets. I have used this for over 29 years on all my brake jobs, and it truly stops brakes from squeaking.

Where to Lube Squeaking Drum Brakes

Rusted Drum Brakes

Bonus Noise: Scraping From Plate or Rock Hitting Rotor

Scraping Noise From Wheel While Driving

More on Brakes by Eddie Carrara

- Brake Noises, What Causes Brake Noises and How to Fix Them

Three of the most common brake noises I encounter on a daily basis. Some of the repairs I share with you here are not common and you will never find them in a service manual or Technical Service Bulletin. - Brake Problems? Answers to Five Common Brake Problems With a Car

Help with diagnosing a brake issue. Five of the most commonly encountered brake problems.

Give Me Your Feedback!

As always, leave me your feedback and comments. All questions are welcome, and no question is stupid. Describe your problem the best you can, and sooner or later we will reach a conclusion and come up with a solution.